ISO 80369-7 Luer Connector Gauge with 6% Taper

2026-01-09

.gtr-container-x7y8z9 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 20px;

box-sizing: border-box;

max-width: 100%;

overflow-x: hidden;

}

.gtr-container-x7y8z9 p {

margin-bottom: 1em;

text-align: left !important;

font-size: 14px;

}

.gtr-container-x7y8z9 .gtr-heading {

font-size: 18px;

font-weight: bold;

margin-top: 2em;

margin-bottom: 1em;

color: #222;

text-align: left;

}

.gtr-container-x7y8z9 .gtr-subheading {

font-size: 16px;

font-weight: bold;

margin-top: 1.5em;

margin-bottom: 0.8em;

color: #333;

text-align: left;

}

.gtr-container-x7y8z9 .gtr-strong {

font-weight: bold;

}

.gtr-container-x7y8z9 img {

margin-top: 2em;

margin-bottom: 1em;

}

.gtr-container-x7y8z9 .gtr-image-caption {

font-size: 13px;

color: #666;

text-align: center;

margin-top: 0.5em;

margin-bottom: 2em;

}

.gtr-container-x7y8z9 .gtr-table-wrapper {

overflow-x: auto;

margin-bottom: 2em;

}

.gtr-container-x7y8z9 table {

width: 100%;

border-collapse: collapse;

margin-bottom: 1em;

font-size: 14px;

border: 1px solid #ccc !important;

}

.gtr-container-x7y8z9 th,

.gtr-container-x7y8z9 td {

padding: 8px 12px;

text-align: left;

vertical-align: top;

border: 1px solid #ccc !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-container-x7y8z9 th {

font-weight: bold;

background-color: #f0f0f0;

color: #333;

}

.gtr-container-x7y8z9 tbody tr:nth-child(even) {

background-color: #f9f9f9;

}

.gtr-container-x7y8z9 ul {

list-style: none !important;

padding-left: 20px;

margin-bottom: 1em;

}

.gtr-container-x7y8z9 ul li {

position: relative;

padding-left: 1.5em;

margin-bottom: 0.5em;

font-size: 14px;

text-align: left;

list-style: none !important;

}

.gtr-container-x7y8z9 ul li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #007bff;

font-size: 1.2em;

line-height: 1;

}

.gtr-container-x7y8z9 ol {

list-style: none !important;

padding-left: 25px;

margin-bottom: 1em;

}

.gtr-container-x7y8z9 ol li {

position: relative;

padding-left: 2em;

margin-bottom: 0.5em;

font-size: 14px;

text-align: left;

counter-increment: none;

list-style: none !important;

}

.gtr-container-x7y8z9 ol li::before {

content: counter(list-item) "." !important;

position: absolute !important;

left: 0 !important;

color: #007bff;

font-weight: bold;

width: 1.5em;

text-align: right;

}

.gtr-container-x7y8z9 .gtr-highlight {

border: 1px solid #007bff;

padding: 15px;

margin-top: 2em;

margin-bottom: 2em;

border-radius: 4px;

}

@media (min-width: 768px) {

.gtr-container-x7y8z9 {

padding: 30px 50px;

}

.gtr-container-x7y8z9 .gtr-heading {

font-size: 24px;

}

.gtr-container-x7y8z9 .gtr-subheading {

font-size: 18px;

}

.gtr-container-x7y8z9 .gtr-table-wrapper {

overflow-x: visible;

}

}

ISO 80369-7:2021 – Dimensional and Performance Standards for Luer Connectors and Reference Gauges

In medical device engineering, small-bore connector integrity is essential for patient safety and system reliability. ISO 80369-7:2021, "Small-bore connectors for liquids and gases in healthcare applications - Part 7: Connectors for intravascular or hypodermic applications," defines stringent dimensional and functional criteria for Luer connectors. This standard replaces ISO 594-1 and ISO 594-2, incorporating improved tolerances, material classifications, and testing protocols to minimize misconnections and leaks in vascular systems.

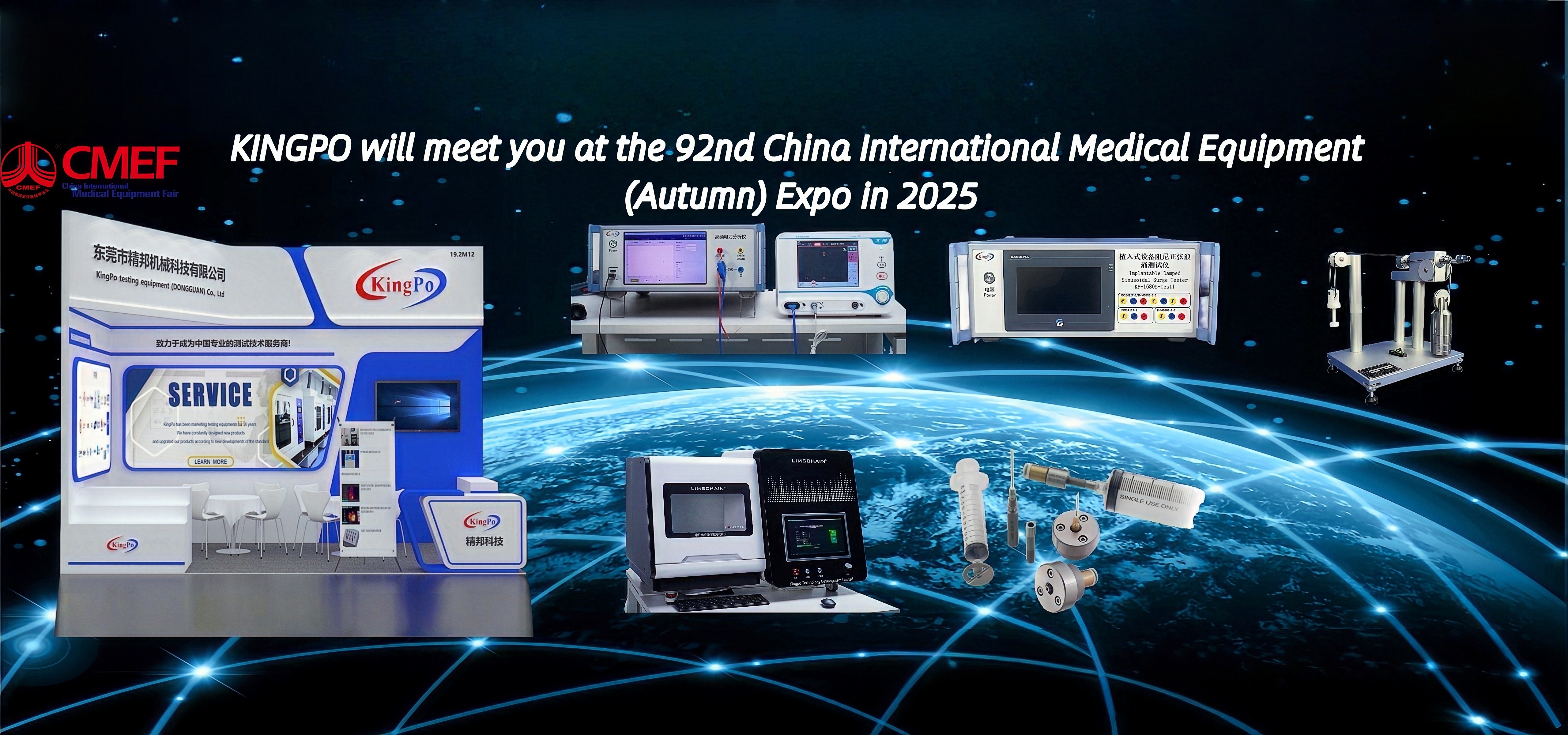

ISO 80369-7 Male Plug Gauge for Luer Connectors

This technical overview examines ISO 80369-7:2021 in depth, emphasizing minimum standards for male reference plug gauges used to verify female Luer connectors. It includes technical specifications, gauge roles in compliance, key features, and quality assurance implications.

Overview of ISO 80369-7:2021 Standard

ISO released ISO 80369-7:2021 in May 2021 for 6% (Luer) taper small-bore connectors in intravascular or hypodermic applications. It covers slip and lock Luer designs, ensuring non-interconnectability with other ISO 80369 series to avoid cross-connections between different medical systems.

Revisions from 2016 include refined tolerances for manufacturability, distinctions between semi-rigid (700-3,433 MPa modulus) and rigid (>3,433 MPa) materials, and enhanced usability assessments. These align with ISO 80369 goals, stressing tests for fluid/air leakage, stress cracking, axial separation resistance, unscrewing torque, and overriding prevention.

Male Reference Plug Gauges in Compliance Verification

Male reference plug gauges serve as "go/no-go" tools to evaluate female Luer connector dimensional accuracy and functional performance. They replicate the standard's conical taper and thread profiles to detect defects that could cause clinical issues.

Gauges assess taper conformity, thread compatibility, and seal efficacy under conditions like 300 kPa pressure. This is vital for intravenous therapy, hypodermic injections, and fluid delivery, where deviations may cause leaks or contamination.

Reputable manufacturers produce gauges from hardened steel (HRC 58-62) with ISO 17025 calibration for traceability. The 6% taper matches the standard's profile for non-interconnectability and performance testing requirements.

Example Product Specifications: Kingpo ISO 80369-7 Male Plug Gauge

Parameter

Specification

Place of Origin

China

Brand Name

Kingpo

Model Number

ISO 80369-7

Standard

ISO 80369-7

Material

Hardness Steel

Hardness

HRC 58-62

Certification

ISO 17025 Calibration Certificate

Key Design Features

6% taper; 300 kPa pressure rating

Key Specifications and Requirements for Compliant Gauges

ISO 80369-7:2021 specifies reference connectors as gauge benchmarks with the following critical requirements:

Dimensional Tolerances – Annex B drawings for slip and lock connectors ensure leak-proof fits

Material and Hardness – Hardened steel (HRC 58-62) withstands repeated use

Pressure Rating – Validation at 300 kPa simulates medical fluid pressures

Performance Tests (Clause 6) – Comprehensive testing protocols for reliability verification

Mandated Performance Tests

Test Type

Requirement/Details

Minimum Performance

Fluid Leakage

Pressure decay or positive pressure method

No leakage

Sub-Atmospheric Air Leakage

Vacuum application

No leakage

Stress Cracking Resistance

Chemical exposure and load

No cracking

Resistance to Axial Separation

Slip: 35 N; Lock: 80 N (minimum hold)

Sustained for 15 s

Unscrewing Torque (Lock only)

Minimum torque to resist loosening

≥ 0.08 N*m

Resistance to Overriding

Prevent thread damage during assembly

No overriding

ISO 80369-7 reference connector and ISO 80369-20 test apparatus

Enhancing Quality Control and Regulatory Compliance

Using ISO 80369-7 gauges in protocols detects non-conformities early, lowering recall risks and aligning with FDA 21 CFR and EU MDR requirements. Functional testing ensures seals under stress, preventing clinical adverse events.

Key Benefits of Compliance

Risk mitigation against misconnections causing patient harm

Efficiency through traceable calibration processes

Facilitated market access and regulatory approval

Support for innovative material and design development

Frequently Asked Questions

What are ISO 80369-7:2021's primary objectives?

It defines Luer connector dimensions and performance for safe intravascular connections and misconnection prevention.

How do male reference plug gauges verify female Luer connectors?

They evaluate dimensional accuracy, taper engagement, and performance against Annex C references, including leakage and separation testing.

What distinguishes ISO 80369-7 from ISO 594?

ISO 80369-7 adds stricter tolerances, material classes, and integrated slip/lock testing, prioritizing non-interconnectability.

What materials and hardness are required for gauges?

Hardened steel at HRC 58-62 ensures precision and durability for repeated testing.

Why is the 6% taper critical?

It provides conical conformity for secure, leak-resistant fittings in hypodermic and IV systems.

What functional tests does Clause 6 mandate?

Fluid/air leakage, stress cracking, axial resistance (35-80 N), unscrewing torque (≥0.08 N*m), and overriding prevention.

How does ISO 80369-7 handle material rigidities?

It separates semi-rigid and rigid requirements by modulus for design flexibility.

Where to procure compliant reference gauges?

Suppliers like Kingpo, Enersol, and Medi-Luer offer calibrated products meeting standard requirements.

In summary, ISO 80369-7:2021 advances Luer connector standardization, with male reference plug gauges upholding dimensional and performance thresholds. These tools enable superior safety, compliance, and innovation in medical devices.

View More

High-Frequency Electrosurgical Unit (ESU) Testing Challenges: Accurate Measurement for 4-6.75 MHz

2026-01-04

.gtr-container-esutest987 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 15px;

max-width: 100%;

box-sizing: border-box;

border: none;

outline: none;

}

.gtr-container-esutest987 p {

font-size: 14px;

margin-bottom: 1em;

text-align: left !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-container-esutest987 .gtr-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 15px;

color: #0056b3;

text-align: left;

}

.gtr-container-esutest987 .gtr-published-date {

font-size: 12px;

color: #666;

margin-bottom: 20px;

font-style: italic;

text-align: left;

}

.gtr-container-esutest987 .gtr-subtitle {

font-size: 16px;

font-weight: bold;

margin-top: 25px;

margin-bottom: 15px;

color: #333;

border-bottom: 1px solid #eee;

padding-bottom: 5px;

text-align: left;

}

.gtr-container-esutest987 strong {

font-weight: bold;

color: #0056b3;

}

.gtr-container-esutest987 ul,

.gtr-container-esutest987 ol {

margin-left: 0;

padding-left: 0;

list-style: none !important;

margin-bottom: 1em;

}

.gtr-container-esutest987 li {

position: relative;

padding-left: 25px;

margin-bottom: 0.5em;

font-size: 14px;

line-height: 1.6;

text-align: left;

list-style: none !important;

}

.gtr-container-esutest987 ul li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #007bff;

font-size: 1.2em;

line-height: 1.6;

top: 0.2em;

}

.gtr-container-esutest987 ol li::before {

content: counter(list-item) "." !important;

position: absolute !important;

left: 0 !important;

width: 1.5em;

text-align: right;

color: #007bff;

font-size: 1em;

line-height: 1.6;

top: 0.2em;

}

.gtr-container-esutest987 .gtr-table-wrapper {

overflow-x: auto;

margin-bottom: 1em;

}

.gtr-container-esutest987 table {

width: 100%;

border-collapse: collapse !important;

border-spacing: 0 !important;

margin-bottom: 1em;

min-width: 600px;

}

.gtr-container-esutest987 th,

.gtr-container-esutest987 td {

border: 1px solid #ccc !important;

padding: 8px !important;

text-align: left !important;

vertical-align: top !important;

font-size: 14px !important;

color: #333;

word-break: normal;

overflow-wrap: normal;

}

.gtr-container-esutest987 th {

font-weight: bold !important;

background-color: #f8f8f8;

color: #0056b3;

}

.gtr-container-esutest987 tbody tr:nth-child(even) {

background-color: #f9f9f9;

}

.gtr-container-esutest987 img {

vertical-align: middle;

}

@media (min-width: 768px) {

.gtr-container-esutest987 {

padding: 20px;

max-width: 960px;

margin: 0 auto;

}

.gtr-container-esutest987 table {

min-width: auto;

}

}

High-Frequency Electrosurgical Unit (ESU) Testing Challenges: Accurate Measurement for 4-6.75 MHz Generators Under IEC 60601-2-2

Published: January 2026

Electrosurgical units (ESUs), also known as electrosurgical generators or "electroknives," are critical medical devices used in surgery for cutting and coagulating tissue with high-frequency electrical current. As ESU technology advances, newer models operate at higher fundamental frequencies, such as 4 MHz or 6.75 MHz, to improve precision and reduce thermal spread. However, testing these high-frequency ESUs poses significant challenges for compliance with IEC 60601-2-2 (the international standard for high-frequency surgical equipment safety and performance).

Common Misconceptions in High-Frequency ESU Testing

A frequent misunderstanding is that external resistors are mandatory for measurements above 4 MHz. This stems from partial interpretations of articles discussing high-frequency load behavior. In reality, the 4 MHz threshold is illustrative only—not a strict rule.

High-frequency load resistors are affected by:

Resistor type (e.g., wire-wound vs. thick-film)

Material composition

Parasitic inductance/capacitance

These factors cause irregular impedance curves at different frequencies. Accurate testing requires verification of resistors using an LCR meter or vector network analyzer to ensure low reactance and phase angle compliance.

Similarly, claims that external resistors are always needed above 4 MHz overlook the core requirements in IEC 60601-2-2.

Key Requirements from IEC 60601-2-2 for Test Equipment

The standard (latest edition: 2017 with Amendment 1:2023) mandates precise instrumentation in clauses related to test equipment (approximately 201.15.101 or equivalent in performance testing sections):

Instruments measuring high-frequency current (including voltmeter/current sensor combinations) must provide true RMS values with ≥5% accuracy from 10 kHz to 5× the fundamental frequency of the ESU mode under test.

Test resistors must have rated power ≥50% of the test load, resistive accuracy preferably within 3%, and impedance phase angle ≤8.5° across the same frequency range.

Voltage instruments require rating ≥150% expected peak voltage, with 5 MHz claims

ESU-2400 / ESU-2400H

BC Group

Up to 8 A

High-power

0–6400 Ω (1 Ω steps)

Graphical waveform display

DFA® technology for pulsed waveforms; strong for complex outputs, bandwidth not explicitly >20 MHz

Key Insight: Manufacturer bandwidth claims typically cover sampling, not full IEC-required accuracy for high-frequency fundamentals. Resistor high-frequency characteristics (phase angle deviations) remain the primary bottleneck.

Non-inductive load resistors are critical for accurate RF testing—verify phase angle at target frequency.

Recommended Best Practices for High-Frequency ESU Testing

To ensure compliance and patient safety:

Use verified non-inductive resistors (custom or tested at specific frequency/power via LCR/network analyzer).

Pair with a high-bandwidth oscilloscope for direct waveform capture and manual calculations.

Observe phase angle (must ≤8.5°) and avoid internal analyzer loads if unverified for your frequency.

For fundamentals ≥4 MHz, avoid relying solely on commercial analyzers—cross-verify with oscilloscope methods.

Medical device testing demands rigor. Hasty or incorrect measurements can compromise safety. Always prioritize verified methods over convenience.

Sources & Further Reading:

IEC 60601-2-2:2017+AMD1:2023

Fluke Biomedical QA-ES III Documentation

Datrend vPad-RF Specifications

Rigel Uni-Therm & BC Group ESU-2400 Product Data

For procurement or custom testing solutions, consult certified biomedical engineers specializing in high-frequency ESU validation.

View More

High frequency electrosurgical tester uses high frequency LCR or mesh above MHz Dynamic compensation implementation of n

2025-10-24

.gtr-container-x7y2z1 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 16px;

max-width: 100%;

box-sizing: border-box;

border: none;

}

@media (min-width: 768px) {

.gtr-container-x7y2z1 {

padding: 24px 40px;

}

}

.gtr-container-x7y2z1 p {

font-size: 14px;

margin-bottom: 1em;

text-align: left !important;

}

.gtr-container-x7y2z1 .gtr-title {

font-size: 18px;

font-weight: bold;

text-align: center;

margin-bottom: 1.5em;

line-height: 1.4;

}

.gtr-container-x7y2z1 .gtr-authors {

font-size: 14px;

text-align: center;

margin-bottom: 1em;

}

.gtr-container-x7y2z1 .gtr-affiliation {

font-size: 14px;

text-align: center;

margin-bottom: 2em;

}

.gtr-container-x7y2z1 .gtr-abstract-heading {

font-size: 14px;

font-weight: bold;

margin-bottom: 0.5em;

text-align: left;

}

.gtr-container-x7y2z1 .gtr-heading-1 {

font-size: 18px;

font-weight: bold;

margin-top: 2em;

margin-bottom: 1em;

line-height: 1.4;

position: relative;

padding-left: 1.5em;

}

.gtr-container-x7y2z1 .gtr-heading-1::before {

content: counter(gtr-section-counter) " " !important;

counter-increment: gtr-section-counter;

position: absolute !important;

left: 0 !important;

color: #007bff;

font-weight: bold;

}

.gtr-container-x7y2z1 .gtr-heading-2 {

font-size: 16px;

font-weight: bold;

margin-top: 1.5em;

margin-bottom: 0.8em;

line-height: 1.4;

position: relative;

padding-left: 2em;

}

.gtr-container-x7y2z1 .gtr-heading-2::before {

content: counter(gtr-section-counter) "." counter(gtr-subsection-counter) " " !important;

counter-increment: gtr-subsection-counter;

position: absolute !important;

left: 0 !important;

color: #007bff;

font-weight: bold;

}

.gtr-container-x7y2z1 .gtr-heading-1,

.gtr-container-x7y2z1 .gtr-heading-2 {

counter-reset: gtr-subsection-counter;

}

.gtr-container-x7y2z1 .gtr-heading-1:not(:first-of-type) {

counter-reset: gtr-subsection-counter;

}

.gtr-container-x7y2z1 .gtr-heading-1:first-of-type {

counter-reset: gtr-section-counter;

}

.gtr-container-x7y2z1 .gtr-heading-1 + .gtr-heading-2 {

counter-reset: gtr-subsection-counter;

}

.gtr-container-x7y2z1 .gtr-image-wrapper {

text-align: center;

margin: 1.5em 0;

}

.gtr-container-x7y2z1 .gtr-image-wrapper img {

display: inline-block;

vertical-align: middle;

}

.gtr-container-x7y2z1 sup {

font-size: 0.75em;

vertical-align: super;

line-height: 0;

}

.gtr-container-x7y2z1 em {

font-style: italic;

}

.gtr-container-x7y2z1 strong {

font-weight: bold;

}

.gtr-container-x7y2z1 ul {

list-style: none !important;

padding-left: 1.5em;

margin-bottom: 1em;

}

.gtr-container-x7y2z1 ul li {

list-style: none !important;

position: relative;

margin-bottom: 0.5em;

padding-left: 1.5em;

}

.gtr-container-x7y2z1 ul li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #007bff;

font-size: 1.2em;

line-height: 1;

}

.gtr-container-x7y2z1 ol {

list-style: none !important;

padding-left: 2em;

margin-bottom: 1em;

counter-reset: gtr-ol-counter;

}

.gtr-container-x7y2z1 ol li {

list-style: none !important;

position: relative;

margin-bottom: 0.5em;

padding-left: 2em;

counter-increment: gtr-ol-counter;

}

.gtr-container-x7y2z1 ol li::before {

content: counter(gtr-ol-counter) "." !important;

position: absolute !important;

left: 0 !important;

color: #007bff;

font-weight: bold;

text-align: right;

width: 1.5em;

}

.gtr-container-x7y2z1 .gtr-table-wrapper {

overflow-x: auto;

margin: 1.5em 0;

}

.gtr-container-x7y2z1 table {

width: 100%;

border-collapse: collapse !important;

border-spacing: 0 !important;

margin: 0 auto;

font-size: 14px;

line-height: 1.4;

}

.gtr-container-x7y2z1 table th,

.gtr-container-x7y2z1 table td {

border: 1px solid #ccc !important;

padding: 8px 12px;

text-align: left;

vertical-align: top;

}

.gtr-container-x7y2z1 table th {

font-weight: bold;

background-color: #f0f0f0;

text-align: center;

}

.gtr-container-x7y2z1 table tr:nth-child(even) {

background-color: #f9f9f9;

}

.gtr-container-x7y2z1 a {

color: #007bff;

text-decoration: none;

}

.gtr-container-x7y2z1 a:hover {

text-decoration: underline;

}

.gtr-container-x7y2z1 .gtr-references ol {

counter-reset: gtr-ref-counter;

}

.gtr-container-x7y2z1 .gtr-references ol li {

counter-increment: gtr-ref-counter;

padding-left: 2.5em;

list-style: none !important;

}

.gtr-container-x7y2z1 .gtr-references ol li::before {

content: "[" counter(gtr-ref-counter) "]" !important;

width: 2em;

}

.gtr-container-x7y2z1 .gtr-author-info {

margin-top: 2em;

padding-top: 1em;

border-top: 1px solid #eee;

}

.gtr-container-x7y2z1 .gtr-author-info p {

margin-bottom: 0.5em;

}

.gtr-container-x7y2z1 .gtr-author-info strong {

display: block;

margin-bottom: 0.5em;

}

@media (max-width: 767px) {

.gtr-container-x7y2z1 table {

width: auto !important;

min-width: 100%;

}

}

Dynamic Compensation Implementation for High-Frequency Electrosurgical Unit Testing Using High-Frequency LCR or Network Analyzers Above MHz

Shan Chao1, Qiang Xiaolong2, Zhang Chao3, Liu Jiming3.

(1. Heilongjiang Institute for Drug Control, Harbin 150088, China; 2. Guangxi Zhuang Autonomous Region Medical Device Testing Center, Nanning 530021, China; 3. Kingpo Technology Development Limited Dongguan 523869; China)

Abstract:

When high-frequency electrosurgical units (ESUs) operate above 1 MHz, the parasitic capacitance and inductance of resistive components result in complex high-frequency characteristics, impacting testing accuracy. This paper proposes a dynamic compensation method based on high-frequency LCR meters or network analyzers for high-frequency electrosurgical unit testers. By employing real-time impedance measurement, dynamic modeling, and adaptive compensation algorithms, the method addresses measurement errors caused by parasitic effects. The system integrates high-precision instruments and real-time processing modules to achieve accurate characterization of ESU performance. Experimental results demonstrate that, within the 1 MHz to 5 MHz range, impedance error is reduced from 14.8% to 1.8%, and phase error is reduced from 9.8 degrees to 0.8 degrees, validating the method's effectiveness and robustness. Extended studies explore algorithm optimization, adaptation for low-cost instruments, and applications across a broader frequency range.

introduction

The electrosurgical unit (ESU) is an indispensable device in modern surgery, using high-frequency electrical energy to achieve tissue cutting, coagulation, and ablation. Its operating frequency typically ranges from 1 MHz to 5 MHz to reduce neuromuscular stimulation and improve energy transfer efficiency. However, at high frequencies, parasitic effects of resistive components (such as capacitance and inductance) significantly affect impedance characteristics, making traditional testing methods incapable of accurately characterizing ESU performance. These parasitic effects not only affect output power stability but can also lead to uncertainty in energy delivery during surgery, increasing clinical risk.

Traditional ESU testing methods are typically based on static calibration, using fixed loads for measurement. However, in high-frequency environments, parasitic capacitance and inductance vary with frequency, leading to dynamic changes in impedance. Static calibration cannot adapt to these changes, and measurement errors can be as high as 15%[2]. To address this issue, this paper proposes a dynamic compensation method based on a high-frequency LCR meter or network analyzer. This method compensates for parasitic effects through real-time measurement and an adaptive algorithm to ensure test accuracy.

The contributions of this paper include:

A dynamic compensation framework based on a high-frequency LCR meter or network analyzer is proposed.

A real-time impedance modeling and compensation algorithm was developed for frequencies above 1 MHz.

The effectiveness of the method was verified through experiments, and its application potential on low-cost instruments was explored.

The following sections will introduce the theoretical basis, method implementation, experimental verification and future research directions in detail.

Theoretical analysis

High frequency resistance characteristics

In high-frequency environments, the ideal model of resistor components no longer applies. Actual resistors can be modeled as a composite circuit consisting of parasitic capacitance (Cp) and parasitic inductance (Lp), with an equivalent impedance of:

Where Z is the complex impedance, R is the nominal resistance, ω is the angular frequency, and j is the imaginary unit. The parasitic inductance Lp and parasitic capacitance Cp are determined by the component material, geometry, and connection method, respectively. Above 1 MHz, ω Lp and

The contribution of is significant, resulting in nonlinear changes in impedance magnitude and phase.

For example, for a nominal 500 Ω resistor at 5 MHz, assuming Lp = 10 nH and Cp = 5 pF, the imaginary part of the impedance is:

Substituting the numerical value, ω = 2π × 5 × 106rad/s, we can obtain:

This imaginary part indicates that parasitic effects significantly affect the impedance, causing measurement deviations.

Dynamic compensation principle

The goal of dynamic compensation is to extract parasitic parameters through real-time measurement and deduct their effects from the measured impedance. LCR meters calculate impedance by applying an AC signal of known frequency and measuring the amplitude and phase of the response signal. Network analyzers analyze reflection or transmission characteristics using S-parameters (scattering parameters), providing more accurate impedance data. Dynamic compensation algorithms use this measurement data to construct a real-time impedance model and correct for parasitic effects.

The impedance after compensation is:

This method requires high-precision data acquisition and fast algorithm processing to adapt to the dynamic working conditions of the ESU. Combining Kalman filtering technology can further improve the robustness of parameter estimation and adapt to noise and load changes [3].

method

System Architecture

The system design integrates the following core components:

High-frequency LCR meter or network analyzer: such as the Keysight E4980A (LCR meter, 0.05% accuracy) or the Keysight E5061B (network analyzer, supports S-parameter measurements) for high-precision impedance measurements.

Signal acquisition unit: collects impedance data in the range of 1 MHz to 5 MHz, with a sampling rate of 100 Hz.

Processing unit: uses an STM32F4 microcontroller (running at 168 MHz) to run the real-time compensation algorithm.

Compensation module: Adjusts the measured value based on the dynamic model and contains a digital signal processor (DSP) and dedicated firmware.

The system communicates with the LCR meter/network analyzer via USB or GPIB interfaces, ensuring reliable data transmission and low latency. The hardware design incorporates shielding and grounding for high-frequency signals to reduce external interference. To enhance system stability, a temperature compensation module has been added to correct for the effects of ambient temperature on the measuring instrument.

Motion compensation algorithm

The motion compensation algorithm is divided into the following steps:

Initial calibration: Measure the impedance of a reference load (500 Ω) at known frequencies (1 MHz, 2 MHz, 3 MHz, 4 MHz, and 5 MHz) to establish a baseline model.

Parasitic parameter extraction: The measured data is fitted using the least squares method to extract R, Lp, and Cp. The fitting model is based on:

Real-time compensation: Calculate the corrected impedance based on the extracted parasitic parameters:

Where ^(x)k is the estimated state (R, Lp, Cp), Kk is the Kalman gain, zk is the measurement value, and H is the measurement matrix.

To improve algorithm efficiency, a fast Fourier transform (FFT) is used to preprocess the measurement data and reduce computational complexity. Furthermore, the algorithm supports multi-threaded processing to perform data acquisition and compensation calculations in parallel.

Implementation details

The algorithm was prototyped in Python and then optimized and ported to C to run on an STM32F4. The LCR meter provides a 100 Hz sampling rate via the GPIB interface, while the network analyzer supports higher frequency resolution (up to 10 MHz). The compensation module's processing latency is kept to under 8.5 ms, ensuring real-time performance. Firmware optimizations include:

Efficient floating point unit (FPU) utilization.

Memory-optimized data buffer management, supporting 512 KB cache.

Real-time interrupt processing ensures data synchronization and low latency.

To accommodate different ESU models, the system supports multi-frequency scanning and automatic parameter adjustment based on a pre-set database of load characteristics. Furthermore, a fault detection mechanism has been added. When measurement data is abnormal (such as parasitic parameters outside the expected range), the system will trigger an alarm and recalibrate.

Experimental verification

Experimental setup

The experiments were conducted in a laboratory environment using the following equipment:

High-frequency ESU: operating frequency 1 MHz to 5 MHz, output power 100 W.

LCR table: Keysight E4980A, accuracy 0.05%.

Network analyzer: Keysight E5061B, supports S-parameter measurements.

Reference load: 500 Ω ± 0.1% precision resistor, rated power 200 W.

Microcontroller: STM32F4, running at 168 MHz.

The experimental load consisted of ceramic and metal film resistors to simulate the diverse load conditions encountered during actual surgery. Test frequencies were 1 MHz, 2 MHz, 3 MHz, 4 MHz, and 5 MHz. The ambient temperature was controlled at 25°C ± 2°C, and the humidity was 50% ± 10% to minimize external interference.

Experimental results

Uncompensated measurements show that the impact of parasitic effects increases significantly with frequency. At 5 MHz, the impedance deviation reaches 14.8%, and the phase error is 9.8 degrees. After applying dynamic compensation, the impedance deviation is reduced to 1.8%, and the phase error is reduced to 0.8 degrees. Detailed results are shown in Table 1.

The experiment also tested the algorithm's stability under non-ideal loads (including high parasitic capacitance, Cp = 10pF). After compensation, the error was kept within 2.4%. Furthermore, repeated experiments (averaging 10 measurements) verified the system's repeatability, with a standard deviation of less than 0.1%.

Table 1: Measurement accuracy before and after compensation

frequency ( MHz )

Uncompensated impedance error (%)

Impedance error after compensation (%)

Phase error ( Spend )

1

4.9

0.7

0.4

2

7.5

0.9

0.5

3

9.8

1.2

0.6

4

12.2

1.5

0.7

5

14.8

1.8

0.8

Performance Analysis

The compensation algorithm has a computational complexity of O(n), where n is the number of measurement frequencies. Kalman filtering significantly improves the stability of parameter estimation, especially in noisy environments (SNR = 20 dB). The overall system response time is 8.5 ms, meeting real-time testing requirements. Compared to traditional static calibration, the dynamic compensation method reduces measurement time by approximately 30%, improving test efficiency.

discuss

Method advantages

The dynamic compensation method significantly improves the accuracy of high-frequency electrosurgical testing by processing parasitic effects in real time. Compared with traditional static calibration, this method can adapt to dynamic changes in the load and is particularly suitable for complex impedance characteristics in high-frequency environments. The combination of LCR meters and network analyzers provides complementary measurement capabilities: LCR meters are suitable for fast impedance measurements, and network analyzers perform well in high-frequency S-parameter analysis. In addition, the application of Kalman filtering improves the algorithm's robustness to noise and load changes [4].

limitation

Although the method is effective, it has the following limitations:

Instrument cost: High-precision LCR meters and network analyzers are expensive, which limits the popularity of this method.

Calibration needs: The system needs to be calibrated regularly to adapt to instrument aging and environmental changes.

Frequency range: The current experiment is limited to below 5 MHz, and the applicability of higher frequencies (such as 10 MHz) needs to be verified.

Optimization direction

Future improvements can be made in the following ways:

Low-cost instrument adaptation: Develop a simplified algorithm based on a low-cost LCR meter to reduce system cost.

Wideband support: The algorithm is extended to support frequencies above 10 MHz to meet the needs of new ESUs.

Artificial intelligence integration: Introducing machine learning models (such as neural networks) to optimize parasitic parameter estimation and improve the level of automation.

in conclusion

This paper proposes a dynamic compensation method based on a high-frequency LCR meter or network analyzer for accurate measurements above 1 MHz for high-frequency electrosurgical testers. Through real-time impedance modeling and an adaptive compensation algorithm, the system effectively mitigates measurement errors caused by parasitic capacitance and inductance. Experimental results demonstrate that within the 1 MHz to 5 MHz range, the impedance error is reduced from 14.8% to 1.8%, and the phase error is reduced from 9.8 degrees to 0.8 degrees, validating the effectiveness and robustness of the method.

Future research will focus on algorithm optimization, low-cost instrument adaptation, and application over a wider frequency range. Integration of artificial intelligence technologies (such as machine learning models) can further improve parameter estimation accuracy and system automation. This method provides a reliable solution for high-frequency electrosurgical unit testing and has important clinical and industrial applications.

References

GB9706.202-2021 "Medical electrical equipment - Part 2-2: Particular requirements for the basic safety and essential performance of high-frequency surgical equipment and high-frequency accessories" [S]

JJF 1217-2025. High-Frequency Electrosurgical Unit Calibration Specification [S]

Chen Guangfei. Research and design of high-frequency electrosurgical analyzer[J]. Beijing Biomedical Engineering, 2009, 28(4): 342-345.

Huang Hua, Liu Yajun. Brief analysis of the power measurement and acquisition circuit design of QA-Es high-frequency electrosurgical analyzer[J]. China Medical Equipment, 2013, 28(01): 113-115.

Chen Shangwen, Performance testing and quality control of medical high-frequency electrosurgical unit[J]. Measuring and Testing Technology, 2018, 45(08): 67~69.

Chen Guangfei, Zhou Dan. Research on calibration method of high-frequency electrosurgical analyzer[J]. Medical and Health Equipment, 2009, 30(08): 9~10+19.

Duan Qiaofeng, Gao Shan, Zhang Xuehao. Discussion on high-frequency leakage current of high-frequency surgical equipment. J. China Medical Device Information, 2013, 19(10): 159-167.

Zhao Yuxiang, Liu Jixiang, Lu Jia, et al., Practice and discussion of high-frequency electrosurgical unit quality control testing methods. China Medical Equipment, 2012, 27(11): 1561-1562.

He Min, Zeng Qiao, Liu Hanwei, Wu Jingbiao (corresponding author). Analysis and comparison of high-frequency electrosurgical unit output power test methods [J]. Medical Equipment, 2021, (34): 13-0043-03.

About the Author

Author profile: Shan Chao, senior engineer, research direction: medical device product quality testing and evaluation and related research.

Author profile: Qiang Xiaolong, deputy chief technician, research direction: active medical device testing quality evaluation and standardization research.

Author profile: Liu Jiming, undergraduate, research direction: measurement and control design and development.

Corresponding author

Zhang Chao, Master, focuses on measurement and control design and development. Email: info@kingpo.hk

View More

Optimize Efficiency with a Battery Testing Machine

2025-10-14

Optimize Efficiency with a Battery Testing Machine

Battery testing machines are vital tools in today's tech-driven world. They ensure batteries perform at their best.

These machines help identify potential issues before they become major problems. This can save time and money.

From simple handheld devices to advanced bench-top models, battery testers come in many forms. Each serves a unique purpose.

Industries like automotive and electronics rely heavily on these machines. They help maintain the efficiency and safety of battery-powered equipment.

Understanding how to choose and use a battery testing machine is crucial. It can extend battery life and enhance performance.

What Is a Battery Testing Machine?

A battery testing machine evaluates the health and performance of batteries. It provides crucial insights into a battery's functionality.

These devices can measure important metrics. For example, the state of charge (SOC) and the state of health (SOH). Such metrics help determine the battery's current condition and remaining lifespan.

There are several types of battery testing machines, each designed for specific functions. Here are common features:

Digital displays for clear readings.

Compatibility with various battery chemistries like lead-acid and lithium-ion.

Ability to perform load, capacity, and impedance tests.

These machines are vital tools in industries and workshops worldwide.

Why Battery Testing Matters

Battery testing plays a critical role in maintaining equipment efficiency. It prevents unexpected failures by providing early warnings about potential battery issues. This proactive approach helps avoid costly downtime.

Regular battery testing can significantly extend battery lifespan. By identifying issues early, users can perform timely maintenance. This not only improves performance but also saves money in the long run.

Key reasons why battery testing is crucial:

Ensures optimal equipment performance.

Reduces risk of sudden battery failures.

Extends battery service life.

Industries relying on batteries, like automotive and electronics, highly benefit from consistent testing practices.

Types of Battery Testing Machines

Battery testing machines come in various forms to cater to diverse needs. From simple devices to advanced systems, each serves a specific purpose. Understanding these types is vital for selecting the right one.

Handheld battery testers are portable and user-friendly. They are ideal for quick checks in fieldwork. Despite their simplicity, they provide useful insights into battery health.

Bench-top testers offer more advanced testing capabilities. They can perform various tests, such as load, capacity, and impedance tests. These machines are suitable for detailed diagnostics and research applications.

Some specialized testers are designed for specific battery chemistries. For instance, some are optimized for lead-acid batteries, while others focus on lithium-ion types. Selecting a tester that suits your battery chemistry is essential.

Key types of battery testers include:

Handheld testers

Bench-top machines

Chemistry-specific testers

by AMIRALI NASIRI (https://unsplash.com/@amiralinasiri)

Key Features to Look For in a Battery Tester

When selecting a battery tester, focus on a few key features. These features ensure that the tester meets your specific needs and provides accurate results.

Accuracy is paramount. A battery tester should give precise readings, ensuring you get a true picture of battery health. Compatibility with various battery types enhances its utility.

Ease of use is another important feature. A user-friendly interface simplifies the testing process, making it accessible to everyone. For professionals, advanced features might be necessary.

Consider testers with data logging capabilities. This feature allows for tracking performance over time, which is crucial for preventive maintenance. It helps identify trends and potential issues early.

Key features to consider:

Accuracy

Battery compatibility

Ease of use

Data logging capabilities

by Brett Jordan (https://unsplash.com/@brett_jordan)

How Battery Testing Machines Work

Battery testing machines evaluate the health and performance of batteries. They assess parameters like voltage, current, and resistance.

The testing process often begins with connecting the tester to the battery. The machine then performs assessments like load tests or impedance measurements. These tests determine the battery's state of charge and health.

Various testing methods provide insights into different aspects of battery performance. For example, load tests measure how well a battery can maintain voltage under load. Impedance tests offer details about the battery's internal resistance, highlighting its capacity.

Key testing methods include:

Voltage measurement

Load testing

Impedance testing

by Kumpan Electric (https://unsplash.com/@kumpan_electric)

Applications: Who Uses Battery Testing Machines?

Battery testing machines serve various industries essential for their operations. They are vital tools in both consumer electronics and industrial sectors.

The automotive industry, for instance, relies heavily on battery testers. They are used to assess vehicle batteries to prevent unexpected failures. Similarly, electronics manufacturers use these machines for quality control and to ensure long-lasting products.

Several professionals benefit from battery testing devices, including:

Automotive technicians

Electronics engineers

Industrial maintenance workers

Field service technicians

Additionally, hobbyists find these tools useful for maintaining personal devices. Battery testers help hobbyists ensure their gadgets function optimally.

by Robin Glauser (https://unsplash.com/@nahakiole)

How to Choose the Right Battery Testing Machine

Selecting the perfect battery testing machine requires careful consideration. Your choice should depend on specific needs and battery types you frequently encounter.

Firstly, evaluate the range of batteries you work with regularly. Consider machines compatible with various chemistries like lead-acid, lithium-ion, and nickel-metal hydride.

Next, think about the key features essential for your operations. Prioritize factors such as:

Accuracy of readings

Ease of use and user interface

Compatibility with diverse battery types

Portability and design

Additionally, budget should align with features without compromising quality. Investing in a reliable tester can prevent costly failures and extend battery life.

by Dai (https://unsplash.com/@nicetomeetyou)

Battery Testing Best Practices and Safety Tips

Implementing best practices ensures accurate results and safety during battery testing. Begin by reading the manual for each battery tester to understand its functions and limitations.

Follow these safety tips to prevent accidents:

Always wear protective gear like gloves and goggles.

Ensure the testing area is well-ventilated.

Avoid using damaged testers or connecting wires.

Regular maintenance of your testing equipment is crucial. This practice prolongs the device's lifespan and maintains testing accuracy. Proper training for operators is also essential, ensuring tests are conducted safely and effectively.

Conclusion: The Value of Reliable Battery Testing

Battery testing machines are indispensable tools across various industries. They ensure the reliable performance and safety of battery-powered systems. Regular testing helps identify potential faults before they escalate into costly issues.

Investing in a high-quality battery tester can save money over time. It prolongs battery life and enhances performance, reducing the need for frequent replacements. For any professional, a battery tester is not just a tool, but an investment in efficiency and safety. Embrace regular battery testing to optimize battery usage and reduce operational risks.

View More

Application of KP2021 High-Frequency Electrosurgical Analyzer and Network Analyzer in Thermage Testing

2025-09-08

.gtr-container-f8g9h0 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

font-size: 14px;

line-height: 1.6;

color: #333;

max-width: 100%;

padding: 15px;

box-sizing: border-box;

}

.gtr-container-f8g9h0 .gtr-heading-main {

font-size: 18px;

font-weight: bold;

margin-top: 25px;

margin-bottom: 15px;

color: #222;

}

.gtr-container-f8g9h0 .gtr-heading-sub {

font-size: 16px;

font-weight: bold;

margin-top: 20px;

margin-bottom: 10px;

color: #333;

}

.gtr-container-f8g9h0 .gtr-heading-minor {

font-size: 15px;

font-weight: bold;

margin-top: 15px;

margin-bottom: 8px;

color: #444;

}

.gtr-container-f8g9h0 p {

margin-bottom: 1em;

text-align: left !important;

color: #333;

}

.gtr-container-f8g9h0 strong {

font-weight: bold;

color: #0056b3;

}

.gtr-container-f8g9h0 ul {

margin: 1em 0;

padding: 0;

list-style: none !important;

}

.gtr-container-f8g9h0 ul li {

position: relative;

padding-left: 25px;

margin-bottom: 0.5em;

line-height: 1.6;

color: #333;

}

.gtr-container-f8g9h0 ul li::before {

content: "•";

position: absolute;

left: 0;

color: #0056b3;

font-weight: bold;

font-size: 1.2em;

line-height: 1.6;

top: 0;

}

.gtr-container-f8g9h0 ol {

margin: 1em 0;

padding: 0;

list-style: none !important;

counter-reset: list-item;

}

.gtr-container-f8g9h0 ol li {

position: relative;

padding-left: 30px;

margin-bottom: 0.5em;

line-height: 1.6;

color: #333;

}

.gtr-container-f8g9h0 ol li::before {

content: counter(list-item) ".";

counter-increment: none;

position: absolute;

left: 0;

color: #0056b3;

font-weight: bold;

text-align: right;

width: 25px;

line-height: 1.6;

top: 0;

}

@media (min-width: 768px) {

.gtr-container-f8g9h0 {

max-width: 960px;

margin: 0 auto;

padding: 30px;

}

.gtr-container-f8g9h0 .gtr-heading-main {

margin-top: 35px;

margin-bottom: 20px;

}

.gtr-container-f8g9h0 .gtr-heading-sub {

margin-top: 25px;

margin-bottom: 12px;

}

.gtr-container-f8g9h0 .gtr-heading-minor {

margin-top: 20px;

margin-bottom: 10px;

}

}

Abstract

Thermage, a non-invasive radiofrequency (RF) skin tightening technology, is widely used in medical aesthetics. With operating frequencies increasing to 1MHz-5MHz, testing faces challenges such as skin effect, proximity effect, and parasitic parameters. Based on the GB 9706.202-2021 standard, this article explores the integrated application of the KP2021 high-frequency electrosurgical analyzer and vector network analyzer (VNA) in power measurement, impedance analysis, and performance validation. Through optimized strategies, these tools ensure the safety and efficacy of Thermage devices.

Keywords: Thermage; KP2021 high-frequency electrosurgical analyzer; network analyzer; high-frequency testing;

IEC 60601-2-20 standard; skin effect; parasitic parameters

Introduction

Thermage is a non-invasive RF skin tightening technology that heats deep collagen layers to promote regeneration, achieving skin tightening and anti-aging effects. As a medical aesthetic device, the stability, safety, and performance consistency of its RF output are critical. According to IEC 60601-2-2 and its Chinese equivalent, GB 9706.202-2021, RF medical devices require testing for output power, leakage current, and impedance matching to ensure clinical safety and efficacy.

High-frequency electrosurgical devices utilize high-density, high-frequency current to create localized thermal effects, vaporizing or disrupting tissue for cutting and coagulation. These devices, typically operating in the 200kHz-5MHz range, are widely used in open surgeries (e.g., general surgery, gynecology) and endoscopic procedures (e.g., laparoscopy, gastroscopy). While traditional electrosurgical units operate at 400kHz-650kHz (e.g., 512kHz) for significant cutting and hemostasis, higher-frequency devices (1MHz-5MHz) enable finer cutting and coagulation with reduced thermal damage, suitable for plastic surgery and dermatology. As higher-frequency devices like low-temperature RF knives and aesthetic RF systems emerge, testing challenges intensify. The GB 9706.202-2021 standard, particularly clause 201.5.4, imposes stringent requirements on measurement instruments and test resistors, rendering traditional methods inadequate.

The KP2021 high-frequency electrosurgical analyzer and vector network analyzer (VNA) play pivotal roles in Thermage testing. This article examines their applications in quality control, production validation, and maintenance, analyzing high-frequency testing challenges and proposing innovative solutions.

Overview and Functions of KP2021 High-Frequency Electrosurgical Analyzer

The KP2021, developed by KINGPO Technology, is a precision testing instrument for high-frequency electrosurgical units (ESUs). Its key features include:

Wide Measurement Range: Power (0-500W, ±3% or ±1W), voltage (0-400V RMS, ±2% or ±2V), current (2mA-5000mA, ±1%), high-frequency leakage current (2mA-5000mA, ±1%), load impedance (0-6400Ω, ±1%).

Frequency Coverage: 50kHz-200MHz, supporting continuous, pulsed, and stimulation modes.

Diverse Test Modes: RF power measurement (monopolar/bipolar), power load curve testing, leakage current measurement, and REM/ARM/CQM (return electrode monitoring) testing.

Automation and Compatibility: Supports automated testing, compatible with brands like Valleylab, Conmed, and Erbe, and integrates with LIMS/MES systems.

Compliant with IEC 60601-2-2, the KP2021 is ideal for R&D, production quality control, and hospital equipment maintenance.

Overview and Functions of Network Analyzer

The vector network analyzer (VNA) measures RF network parameters, such as S-parameters (scattering parameters, including reflection coefficient S11 and transmission coefficient S21). Its applications in medical RF device testing include:

Impedance Matching: Evaluates RF energy transfer efficiency, reducing reflection losses to ensure stable output under varying skin impedances.

Frequency Response Analysis: Measures amplitude and phase responses across a wide band (10kHz-20MHz), identifying distortions from parasitic parameters.

Impedance Spectrum Measurement: Quantifies resistance, reactance, and phase angle via Smith chart analysis, ensuring compliance with GB 9706.202-2021.

Compatibility: Modern VNAs (e.g., Keysight, Anritsu) cover frequencies up to 70GHz with 0.1dB accuracy, suitable for RF medical device R&D and validation.

These capabilities make VNAs ideal for analyzing Thermage’s RF chain, complementing traditional power meters.

Standard Requirements and Technical Challenges in High-Frequency Testing

Overview of GB 9706.202-2021 Standard

Clause 201.5.4 of GB 9706.202-2021 mandates that instruments measuring high-frequency current provide true RMS accuracy of at least 5% from 10kHz to five times the device’s fundamental frequency. Test resistors must have a rated power at least 50% of the test consumption, with resistance component accuracy within 3% and an impedance phase angle not exceeding 8.5° in the same frequency range.

While these requirements are manageable for traditional 500kHz electrosurgical units, Thermage devices operating above 4MHz face significant challenges, as resistor impedance characteristics directly impact power measurement and performance evaluation accuracy.

Key Characteristics of Resistors at High Frequencies

Skin Effect

The skin effect causes high-frequency current to concentrate on a conductor’s surface, reducing effective conductive area and increasing the resistor’s actual resistance compared to DC or low-frequency values. This can lead to power calculation errors exceeding 10%.

Proximity Effect

The proximity effect, occurring alongside the skin effect in closely arranged conductors, exacerbates uneven current distribution due to magnetic field interactions. In Thermage’s RF probe and load designs, this increases losses and thermal instability.

Parasitic Parameters

At high frequencies, resistors exhibit non-negligible parasitic inductance (L) and capacitance (C), forming a complex impedance Z = R + jX (X = XL - XC). Parasitic inductance generates reactance XL = 2πfL, increasing with frequency, while parasitic capacitance generates reactance XC = 1/(2πfC), decreasing with frequency. This results in a phase angle deviation from 0°, potentially exceeding 8.5°, violating standards and risking unstable output or overheating.

Reactive Parameters

Reactive parameters, driven by inductive (XL) and capacitive (XC) reactances, contribute to impedance Z = R + jX. If XL and XC are unbalanced or excessive, the phase angle deviates significantly, reducing power factor and energy transfer efficiency.

Limitations of Non-Inductive Resistors

Non-inductive resistors, designed to minimize parasitic inductance using thin-film, thick-film, or carbon-film structures, still face challenges above 4MHz:

Residual Parasitic Inductance: Even small inductance produces significant reactance at high frequencies.

Parasitic Capacitance: Capacitive reactance decreases, causing resonance and deviating from pure resistance.

Wideband Stability: Maintaining phase angle ≤8.5° and resistance accuracy ±3% from 10kHz-20MHz is challenging.

High-Power Dissipation: Thin-film structures have lower heat dissipation, limiting power handling or requiring complex designs.

Integrated Application of KP2021 and VNA in Thermage Testing

Test Workflow Design

Preparation: Connect KP2021 to the Thermage device, setting load impedance (e.g., 200Ω to simulate skin). Integrate VNA into the RF chain, calibrating to eliminate cable parasitics.

Power and Leakage Testing: KP2021 measures output power, voltage/current RMS, and leakage current, ensuring compliance with GB standards, and monitors REM functionality.

Impedance and Phase Angle Analysis: VNA scans the frequency band, measures S-parameters, and calculates phase angle. If >8.5°, adjust matching network or resistor structure.

High-Frequency Effect Compensation: KP2021’s pulse mode testing, combined with VNA’s time-domain reflectometry (TDR), identifies signal distortions, with digital algorithms compensating for errors.

Validation and Reporting: Integrate data into automated systems, generating GB 9706.202-2021-compliant reports with power load curves and impedance spectra.

KP2021 simulates skin impedances (50-500Ω) to quantify skin/proximity effects and correct readings. VNA’s S11 measurements calculate parasitic parameters, ensuring a power factor close to 1.

Innovative Solutions

Resistor Material and Structure Optimization

Low-Inductance Design: Use thin-film, thick-film, or carbon-film resistors, avoiding wire-wound structures.

Low Parasitic Capacitance: Optimize packaging and pin design to minimize contact area.

Wideband Impedance Matching: Employ parallel low-value resistors to reduce parasitic effects and maintain phase angle stability.

High-Precision High-Frequency Instruments

True RMS Measurement: KP2021 and VNA support non-sinusoidal waveform measurement across 30kHz-20MHz.

Wideband Sensors: Select low-loss, high-linearity probes with controlled parasitic parameters.

Calibration and Validation

Regularly calibrate systems using certified high-frequency sources to ensure accuracy.

Test Environment and Connection Optimization

Short Leads and Coaxial Connections: Use high-frequency coaxial cables to minimize losses and parasitics.

Shielding and Grounding: Implement electromagnetic shielding and proper grounding to reduce interference.

Impedance Matching Networks: Design networks to maximize energy transfer efficiency.

Innovative Testing Methods

Digital Signal Processing: Apply Fourier transforms to analyze and correct parasitic distortions.

Machine Learning: Model and predict high-frequency behavior, auto-adjusting test parameters.

Virtual Instrumentation: Combine hardware and software for real-time monitoring and data correction.

Case Study

In testing a 4MHz Thermage system, initial results showed a 5% power deviation and a 10° phase angle. KP2021 identified excessive leakage current, while VNA detected a 0.1μH parasitic inductance. After replacing with low-inductance resistors and optimizing the matching network, the phase angle dropped to 5°, and power accuracy reached ±2%, meeting standards.

Conclusion

The GB 9706.202-2021 standard highlights the limitations of traditional testing in high-frequency environments. The integrated use of KP2021 and VNA addresses challenges like skin effect and parasitic parameters, ensuring Thermage devices meet safety and efficacy standards. Future advancements, incorporating machine learning and virtual instrumentation, will further enhance testing capabilities for high-frequency medical devices.

https://www.batterytestingmachine.com/videos-51744861-kp2021-electrosurgical-unit-analyzer.html

View More